-

×

5l bleach

1 × R89.99

5l bleach

1 × R89.99 -

×

Fibre Optic Otoscope

1 × R750.87

Fibre Optic Otoscope

1 × R750.87 -

×

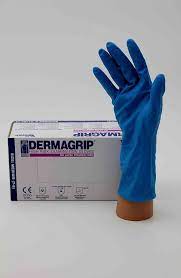

dermagrip nitrile gloves

1 × R319.99

dermagrip nitrile gloves

1 × R319.99

dermagrip hide paste

R319.99 Ex VAT

HIGH RISK GLOVES

These high-risk latex gloves are for personal skin protection. They protect hands during contact with mild solvents, paints and soiling.

Characteristics

An extra thick, powder-free, latex glove with a long shaft of 30cm. This latex glove has an excellent grip for handling spray guns, is solvent resistant, and has a textured surface. The gloves may be used left or right-handed. They are available in two sizes and supplied in a 50-piece dispenser box.

Category: high risk gloves

Tag: dermagrip hide paste

High Risk Gloves

High Risk Gloves provide unparalleled and added protection in high risk situations. Thicker and stronger than normal gloves, these gloves are the ideal choice in situations such as trauma, pharmaceutical waste handling and decontamination

How would you describe surgical gloves?

A sterile glove worn to prevent contamination of the patient during invasive procedures and to protect the hand from exposure to potentially infectious materials.

Heavy duty to Consider When Selecting A Glove:

Gloves are available in disposable or reusable options.

Disposable Gloves

There are many different disposable glove substrates available, each to suit different needs, but there are two main disposable gloves: general purpose and medical/exam grade gloves.

General Purpose Gloves

General purpose gloves are commonly used for:

Food handling

JanitorialGloves

Salons/Spas

Automotive

Medical or Exam Grade Gloves

Medical gloves include:

Examination gloves

Surgical gloves

Chemotherapy Gloves

Other healthcare gloves

They have specific standards from the FDA Heavy duty they must adhere to.

The material that the glove is made from will affect the level of protection, comfort, durability and more. Disposable gloves are for one-time use and should only be used for one task. They should be discarded after every use.

Reusable Gloves

Reusable gloves, sometimes labeled as industrial or heavy-duty, offer greater protection and are less likely to tear in use than disposables. They also provide greater protection against chemicals and hazardous materials. However, they are thicker than disposable gloves and are less flexible and limit touch sensitivity.

To maintain usefulness, reusable gloves must be washed and dried after every use. Proper care is especially important if the gloves were used with chemicals to avoid cross contamination as well as user injury.

Reusable gloves should be inspected before each use for discoloration or any signs or damage. If any signs of wear and tear are found, they should be discarded. They should also be discarded if the inside of the gloves become contaminated during use.

Commercial Gloves Guide 101

In addition, the National Sanitation Foundation (NSF) has developed a protocol for food service gloves identified as “P155: Disposable Food Contact Gloves.” The P155 protocol establishes criteria for product quality like tensile strength, leakage, an

Cleaning Industry

Gloves used in the janitorial industry are not regulated by the FDA. However, different glove materials have different chemical and tear resistance.

If your staff regularly works with harsh chemicals, make sure you select a glove material that is extremely resistant to chemicals and intended for high risk situations.

Glove Thickness

The thickness of gloves is measured in mils. A mil equals one-thousandth of an inch (0.001 inch). Gloves generally range from 2-15 mils thick.

In general, the thicker the glove, the more protection it provides, but increased thickness will lower touch sensitivity and may make it harder to work. Reusable gloves will be thicker and provide more protection.

Glove Tensile StrengthTensile Strength

Tensile strength is the amount of force or pull it takes to break the glove. Tensile strength is measured in mPa (megaPascal).

The lower the mPa rating, the more likely it is that gloves will easily tear.

Related products

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

R319.99 Ex VAT

high risk gloves

dermagrip high risk examination gloves non latex powder free

R319.99 Ex VAT